Industrial Biotechnology

Novis develops products from sustainable waste materials or using new innovative technologies.

For example, waste materials from organic waste or hop cultivation are used for this purpose.

BW2Pro - Products made from organic waste

The Ministry of the Environment, Climate Protection and the Energy Sector (Baden-Württemberg) has approved the BW2Pro project. Co-financed by EU ERDF funds, a pilot

project for the recycling of biowaste will be carried out at the Backnang disposal plant.

Under the leadership of the University of Hohenheim and the Institute for Water Management (University of Stuttgart), an innovative process for recovering products from organic waste will be

implemented from March 2022. The organic waste will be subjected to thermal pressure hydrolysis, the cooking water will be used in an innovative biogas reactor and the fibers will be processed

into plant pots and tableware. In addition, cellulase and bioplastics (PHA) are also produced by other partners and nutrients are recovered in pure form.

The project is part of the Baden-Württemberg Sustainable Bioeconomy Strategy. Further information here or at www.bw2pro.de.

PHBMAX

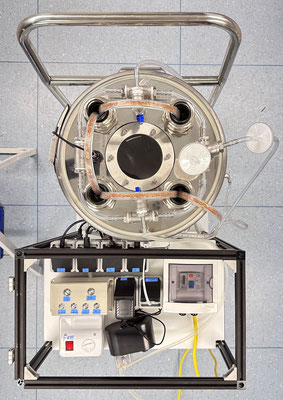

In collaboration with Continental and the University of Tübingen, Novis is working on scaling up PHB production in the PHBMAX project. The declared aim of the project is to develop and operate

photobioreactors. The aim is to create reactors with a total volume of 10m³.

The biomass produced will be used by Continental vollständog to carry out test series.

One aim of the project is to utilize CO₂, which is generated as waste or residual material during production or in industrial processes. The recycling of this raw material and the associated

return to the carbon cycle is economical and supports the fight against climate change.

PHB2PRO

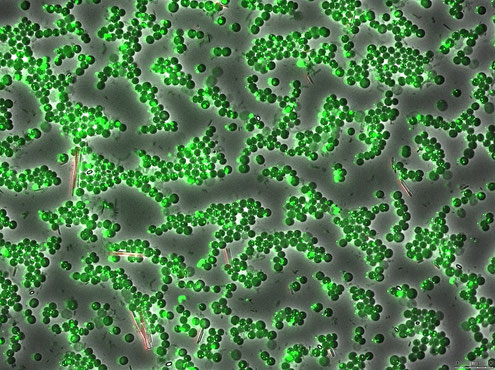

Novis is also working together with the Institute for Plastics Technology in Stuttgart on a similar project involving the pure production of PHB. PHB is also obtained from the biomass of

blue-green algae (cyanobacteria). However, the resulting PHB is separated from the biomass using an extraction process and then further processed by the IKT.

The resulting bioplastic is to be transformed into three-dimensional prototypes for the first time by the DITF (German Institute of Textile and Fiber Research) using a newly developed “meltblown”

process.

Fermentation composite - composite materials from fermented hop vines

Since May 2019, Novis has been working together with the German Institute of Textile and Fiber Research (DITF), the company Hopfenpower and the Nuding joinery on the production of composite

materials from fermented hop residues.

There is a growing market for sustainable and ecological products in the fiber composite industry. The use of natural fibers and bio-based plastics plays a decisive role in this. However, natural

fibers must be specially cultivated and extracted from the plant for material recycling.

The aim of the project is to develop a process chain that leads to a high-quality composite material from fermented hop vines. In this context, Novis is developing the processes for processing

the fibers from the biogas plant.

Hop yarn - cotton substitute products made from hop fibers

In another project related to hop fibers, Novis has been working together with the German Institute of Textile and Fiber Research (DITF), the Leipzig Institute of Plant Genetics and Crop Plant

Research (IPK) and the company Hopfenpower since September 2022.

Cotton as a substitute for artificial bonding fibers is well known and is used worldwide. However, its cultivation requires a lot of space and, above all, water. Hop fibers can fill a raw

material gap here. At the same time, the disposal of hop stalks is improved.

The aim of this project is to provide a process technology for making hop fibers available and ultimately to produce high-quality textile samples, such as shirts and blouses.